BST TV they are going to share a third episode in which they shows their facilities and their ambitions towards satellite mass manufacturing.

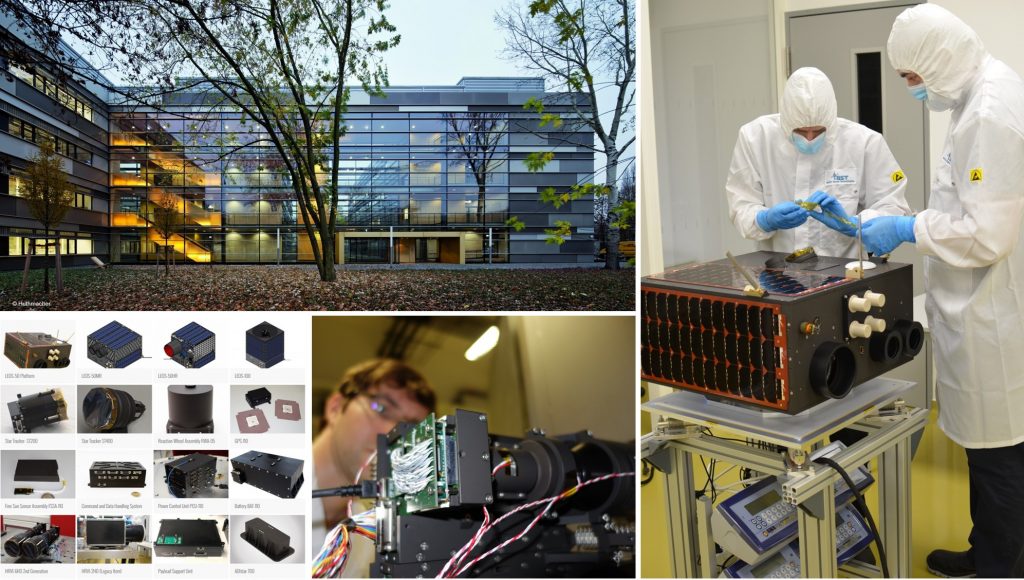

The video gives an inside view of their facility booth in Germany as well as their new factory for mega constellations.

The Need for Speed!

Cubesats and the few factories for satellites (e.g. SpaceX & OneWeb) aside the global production of medium sized satellites is 50-100 per year globally. This production is done by 50+ companies globally which leads to satellite production of one satellites per year of most companies.

With more than 100 constellations and mega constellations upcoming a new way of building satellites is needed. Berlin Space Technologies is at the forefront of this development. They have focused our R&D on mass manufacturing of satellites since the beginning. Automated testing and fully digitized documentation are at the core of the Henry Ford moment but so is having an actual factory.

Meet our Factory

When they lifted the veil of their satellite factory in January they did not know that they were in for a ride. Now Half a year into this pandemic neither they nor their Joint Venture partners from Azista Industries really find the time to do the grand opening ceremony and give all of you the opportunity to visit their facilities. Therefore, they will give you a peak behind the curtains.

Design and Prototype Manufacturing

The design facility is located in Berlin. Here tech wizards make the magic happen that turn ideas into satellites.

In Berlin there is a team of 30 people with decades of experience that works in our 1000m² facility. They are vertically integrated and have the ability to build all of our subsystems in-house. Prototype manufacturing and small series production (<10 devices) is done here.

Large Scale Manufacturing – Our reasons for choosing “Make in India”

Large scale satellite manufacturing that is at the heart of the Henry Ford moment in the space industry is implemented in our two Ahmedabad (India) facilities. India has been chosen by BST for a number of reasons:

- India has a strong tradition in space Systems thanks to decades of experience of the Indian Space Research Organization (ISRO)

- Consequently both the local talent pool as well as the space ecosystem is well developed

- India has a stable and democratic political system and English is spoken throughout the country

- Local launch infrastructure as well as Indian made own rockets are available

Factory #1 Satellite Subsystem Manufacturing

The first factory which is run by our partner Azista is located just 3.5km away from ISRO SAC. It has 5000m² and there are 120 people working on a large number of projects. The facility is certified by ISRO and regularly manufactures subsystems for Indian national programs. Handling of both HiRel projects as well NewSpace approach is continuously implemented.

Factory #2 Satellite System Assembly

The second factory which is run by the Joint Venture of Azista and BST was opened earlier this year has also 5000m². It is located at the outskirts of Ahmedabad. It is sized for hosting 5 assembly lines in parallel. Each one is expected to produce 1 satellites per week, giving it a production rate of 250 satellites per year.

To expand this facility is it planned to implement 20 additional manufacturing lines which will raise the production capability to >1000 satellites per year. The parallel approach makes it easy to add as much capacity as required.

Outlook

The satellite assembly plant (factory #2) is about to wake up for its first production run. While still empty, the process of hiring of the first team is now gathering speed after being delayed due to Covid and subsequent lock-down. The next step is on-boarding and training the satellite manufacturing teams.