In keeping with our theme for 2023, the TAI Design and Sales Team will be featuring common Thermal Strap design and program questions we receive from our customers at NASA, National Laboratories, Cryogenic Engineering Firms, and Aerospace Primes from across the globe. This month’s installment will cover typical test and program questions posed by several recent customers at NASA, Lockheed Martin, and DESY.

Thermal Strap Conductance Testing and Thermal Interface Materials (TIM)

Question: does TAI offer thermal conductance testing, and if so, what are your capabilities and test pricing?

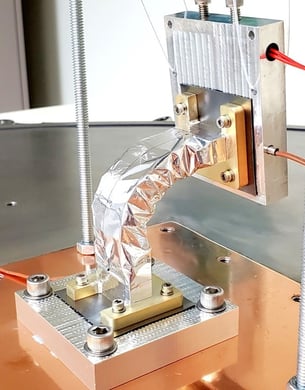

TAI offers thermal conductance testing for all thermal strap products here at our facility. Our test laboratory includes two, custom built vacuum chambers that are designed around our thermal test fixturing and our thermal conductance test procedures (TAI will be releasing our Thermal Strap Conductance Test Work Instruction in a blog next month). Each chamber can test as many as 6-8 straps at a time, depending on size and complexity of the design. Tests are only performed at room temp (~296K), but TAI can make highly accurate predictions at cryogenic temperatures for copper thermal strap products with our conductance projection software, which has been optimized and updated with results from thousands of thermal tests, as well as conductance testing from our national laboratory partners at Fermi and Argonne National Labs, NIST, and several cryostat and cryocooler manufacturing companies in the US and abroad.

|

|

Thermal tests are provided on a complimentary basis for many programs, though in some cases, they will cost either $500 or $1,500 – $2,500 for the first test, depending on the complexity of strap design and subsequent test fixturing that needs to be designed and manufactured by our Design Engineers and Machinists. Conductance testing typically adds 1 week to program lead times, though extensive testing can require additional time.

Question: What Thermal Interface Material (TIM) does TAI recommend and are thermal straps shipped with TIM samples?

This is one of our most common questions. For all thermal conductance tests performed here at TAI, our technicians use a product called eGraf HT1205, by NeoGraf. Through thousands of tests performed over 15 years, HT1205 has proven itself to be the most efficient TIM available (offering slightly better performance than a similar product used by our European Aerospace customers, SigraFlex). However, SigraFlex is typically the only approved, graphite-based TIM in Europe, whereas our North American customers have no issues with the eGraf material.

This is one of our most common questions. For all thermal conductance tests performed here at TAI, our technicians use a product called eGraf HT1205, by NeoGraf. Through thousands of tests performed over 15 years, HT1205 has proven itself to be the most efficient TIM available (offering slightly better performance than a similar product used by our European Aerospace customers, SigraFlex). However, SigraFlex is typically the only approved, graphite-based TIM in Europe, whereas our North American customers have no issues with the eGraf material.

When it comes to colder/cryogenic temperatures, most of our customers prefer Indium Foils, as Indium is the only TIM that continues to work at cryogenic temps and remains malleable (making it effective as a seal). However, some of our national laboratory and university physics department customers will opt for Apiezon N Thermal Grease at cryogenic temperatures as well (there is a terrific paper in the Journal Cryogenics comparing the two materials, found here: https://www.sciencedirect.com/science/article/abs/pii/0011227594901422 ).

TAI can provide complimentary sheets of eGraf HT1205 for most graphite and graphene thermal strap programs, but material is generally not offered with our copper thermal straps.

Question: Does TAI offer Thermal Cycling for thermal strap programs?

TAI does offer in-house thermal cycling for both copper and graphite/graphene thermal strap programs. However, testing is limited to less than 20 cycles, and certain temperature extremes may not be workable with our test methods. For tests with larger ranges than cannot be accommodated with dry ice or our test ovens, or those with several dozen or hundreds of cycles, thermal cycling must be outsourced to a third party test facility, like NTS. TAI performs pre and post-cycling thermal conductance testing to verify performance.

Thermal cycling pricing can cost as little as $1,000, though the price is highly dependent upon the test parameters, number of straps being tested, and whether or not testing must be outsourced to a third party. For more information, contact TAI. Thermal cycling will typically add 1 week to program lead time if performed by TAI. If testing needs to be outsourced to a third party, that will typically add 2-4 weeks to program lead times, depending on the number or tests in their queue, and test parameters. Pre and Post-Cycling Tests will also typically add a total of 1-2 weeks to a program, depending on the number of straps to be tested.

Thermal Strap Program Lead Times

Question: What are the current lead times for copper and graphite thermal strap programs, and are the supply chain issues impacting either?

Typical CuTS® program lead times run 6 weeks for standard models and 7 weeks for customs. However, with our unprecedented rise in business over the last 3 years, and global supply chain issues with OFHC cu plate and cabling, most standard and custom programs are currently quoted at 8 weeks from drawing approval (for smaller programs of less than 15 units, not including optional testing). Expedites are available down to 4 and 6 week lead times depending on quantities and testing. Check with our Director of Business Development for current options.

All graphite and graphene strap programs are running as usual, and relatively unphased by global supply chain issues. Most programs are running 8 weeks for 1-3 prototypes, and thermal conductance testing may increase that to 9-10 weeks. Flight model (FM) orders are still shipping out in 5-6 weeks for most programs. Additional testing (shock and vibration) must be outsourced to third party facilities, and will typically add at least 4 weeks to program lead times.

We hope that clarifies things, and will be posting more questions and answers in the following months.

Copyright 2023 All rights reserved.

Copyright 2023 All rights reserved.